The efficiency and safety of material handling processes hinge greatly on the choice of casters and wheels. Selecting the most suitable type can be the difference between seamless, cost-effective operations and costly mistakes or injuries. Whether you’re equipping warehouse carts or industrial machines, factoring in the specific requirements of your workplace is crucial. For many environments, polyurethane wheels offer an outstanding balance of durability and floor protection, making them a preferred choice for a wide range of applications.

Optimal caster and wheel selection improves workplace safety, reduces maintenance demands, and extends equipment lifespan. Businesses can minimize downtime and safeguard their workers from unnecessary hazards by understanding the correlations between wheel composition, load distribution, and ergonomic movement. Proper selection directly impacts operational productivity and supports compliance with occupational safety standards.

When evaluating your options, it is important to weigh immediate functional needs and long-term efficiency. Considering the type of surfaces the wheels will encounter, the expected load, and exposure to challenging environmental elements, all contribute to selecting a caster that operates smoothly with minimal disruption. Investing time up front to choose wisely pays ongoing dividends in cost savings and operational reliability.

Understanding Load Capacity

One of the most critical aspects when choosing casters is the load capacity. Each caster is rated for a specific weight, and exceeding this limit can damage the wheel and mounting and create a hazardous working environment. Overburdening casters will increase rolling resistance and accelerate wear, leading to costly repairs and unplanned downtime. Ensuring the combined capacity of all casters on a piece of equipment matches or exceeds the intended load is essential for maintaining safety and functionality. Detailed load limits can typically be found in product specifications—review them closely to avoid the common pitfalls associated with underestimating load requirements.

Choosing the Right Wheel Material

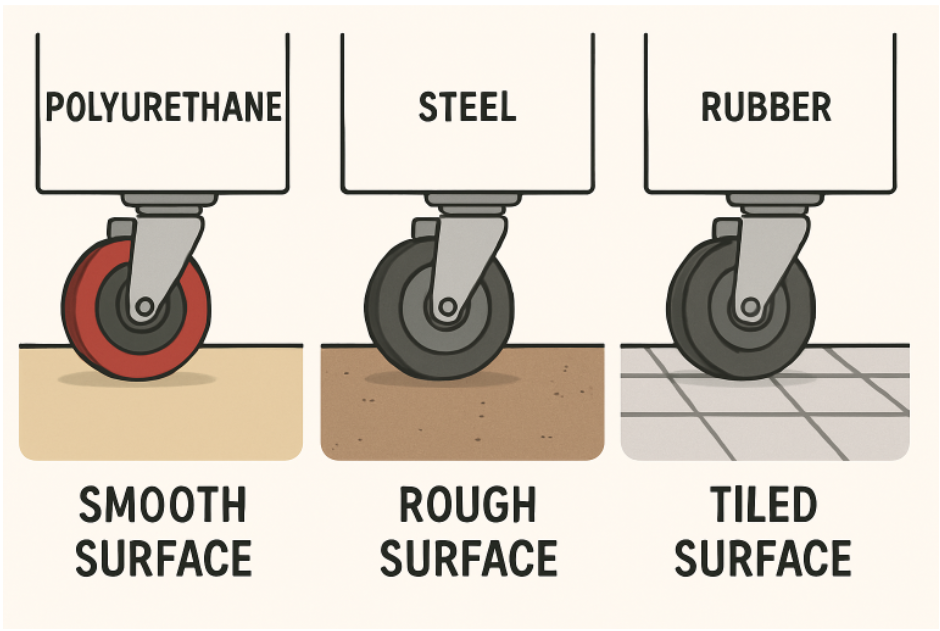

Wheel material impacts both the ease of movement and the protection of flooring surfaces. Polyurethane wheels provide low rolling resistance, absorb vibration, and resist chemicals or oils, making them a practical choice for many settings. In contrast, steel wheels excel in environments with rough or abrasive floors, offering high load capacity and resistance to deformation. Rubber wheels can cushion loads but may leave marks on finished floors, so consider the surrounding environment and usage level when selecting wheel types. Matching wheel material to your operational needs directly influences equipment longevity and the safety of your workforce.

Considering Floor Type and Environment

Considering Floor Type and Environment

The specific surface casters that will traverse are another vital consideration. Hard, even floors allow hard-tread wheels like polyurethane or phenolic resin that minimize resistance and decrease operator fatigue. For uneven surfaces or outdoor use, soft-tread wheels—such as those made of neoprene or pneumatic tires—help absorb shocks and prevent jarring loads, protecting equipment and cargo. Environmental factors, including temperature fluctuations, exposure to corrosive chemicals, or persistent humidity, should also inform caster choice to prevent premature failure and ensure smooth operation.

Enhancing Ergonomics and Safety

Ergonomics are deeply affected by caster and wheel specifications. Features such as precision ball bearings, wider tread profiles, and easy-swivel designs can significantly reduce operators’ push or pull effort. By choosing ergonomically designed casters, businesses reduce the risk of strains and workplace injuries, fostering a safer and more efficient workflow. Such investments pay off with fewer workers’ compensation claims and boost employee satisfaction.

Maintenance and Longevity

Even the most robust casters require regular care to ensure optimal function and maximum lifespan. Maintenance-free casters with sealed bearings are ideal for high-usage environments as they remove dust and debris, minimizing downtime due to cleaning or repairs. Establishing routine inspection schedules helps detect issues such as worn treads, loose fasteners, or misalignment early, permitting swift intervention before breakdowns occur. Choosing casters built with longevity ensures your material handling equipment remains reliable for years, reducing the total cost of ownership and minimizing interruptions to productivity.

Final Thoughts

Selecting the appropriate casters and wheels entails careful analysis of load capacity, materials, floor compatibility, environmental factors, ergonomic implications, and maintenance needs. Businesses can significantly enhance operational efficiency and safeguard employee well-being by making informed choices tailored to specific work environments. Update your caster selection periodically to take advantage of new advancements and to meet your operation’s evolving needs, ensuring continued success and a safe workplace.