Choosing the right industrial adhesive is a crucial decision that can significantly impact the success and longevity of your product or manufacturing process. The vast array of adhesive types can seem overwhelming, yet understanding each step in the selection process will help ensure secure, lasting bonds in demanding environments. If you need a reliable solution for bonding a variety of packaging materials, consider NXT Level Packaging Hot Melt Adhesive, which is specifically designed to meet industrial requirements with efficiency and strength.

Proper bonding starts with recognizing that different adhesives possess unique properties optimized for distinct applications. By carefully matching adhesive characteristics to your materials, environments, and manufacturing processes, you not only guarantee long-term durability but also boost operational productivity and product reliability. When searching for the optimal adhesive, it’s important to follow a systematic evaluation rather than relying solely on brand reputation or initial cost.

Material compatibility, environmental resistance, cure methods, and health and safety compliance are all factors that must be carefully weighed during this crucial selection process. Working with trustworthy suppliers and product data is invaluable, as it provides technical support and confidence in performance outcomes. For insights backed by experts and up-to-date resources, consult guides from recognized industrial publications and adhesive manufacturers.

Understand Your Materials

Understand Your Materials

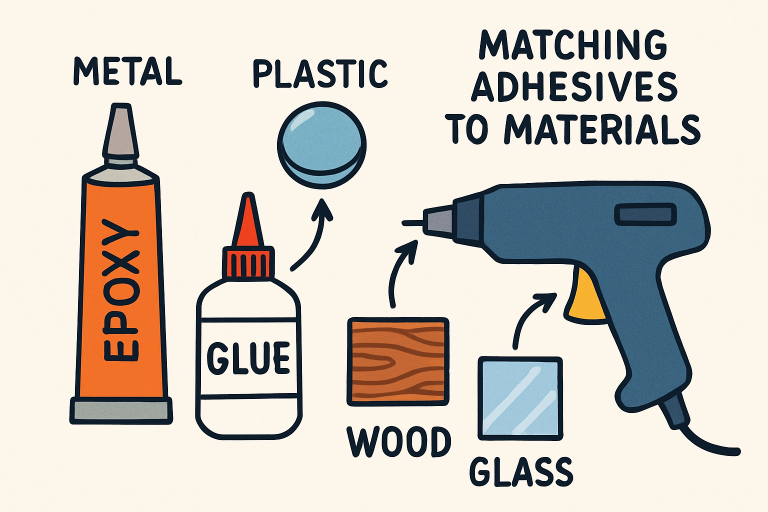

Every adhesive is formulated to bond certain substrates with maximum effectiveness. Whether you’re joining metals, plastics, wood, glass, or composites, it’s crucial to know which adhesive chemistries suit your materials. For example, epoxies are favored for their strength on metals and ceramics, while acrylics are often used when metals must be bonded quickly to plastics. Polyurethanes are ideal when flexibility is needed alongside strength, and silicone adhesives excel where exposure to high temperature or weather is expected.

- Epoxies: Best for metals, ceramics, and many plastics.

- Acrylics: Fast-curing, suitable for metals and plastics.

- Polyurethanes: Flexible, bonds wood, plastics, and composites.

- Silicone Adhesives: Resistant to extreme temperatures, suitable for use with glass and metals.

By matching adhesive formulations to your primary materials, you increase the likelihood of a durable and effective bond.

Consider Environmental Conditions

After examining the materials, consider the environment in which the bond will exist. Adhesive performance fluctuates based on temperature, humidity, chemical exposure, and sunlight. For instance, if your project operates outdoors or in wash-down areas, prioritize options with high moisture and UV resistance. If your process involves exposure to solvents or cleaning chemicals, opt for adhesives proven to withstand these aggressors, ensuring the joint’s longevity under all conditions.

- Temperature Range: Choose based on expected service temperatures.

- Moisture Resistance: Critical for outdoor or wet applications.

- Chemical Resistance: Required for contact with oils, acids, or cleaning agents.

- UV Stability: Essential for joints exposed to sunlight.

This comprehensive evaluation minimizes risk and boosts performance year-round, regardless of exposure.

Evaluate Mechanical Requirements

Not all applications demand the same type of physical strength or resilience. Identify all forces at play: Will the bond experience frequent vibration or flexing? Are shock or impact loads possible? Does the joint need rigid, seamless strength or the ability to flex? Considering these factors ensures the adhesive won’t degrade prematurely or fail at a critical moment. Additionally, consider the cure time: production lines that require rapid throughput may benefit from fast-setting options.

- Load Type: Shear, peel, tensile, or impact resistance required.

- Flexibility: Needed for moving or expanding joints.

- Cure Speed: Align with production requirements and complexity of assembly.

Defining these stresses in the selection process directly influences manufacturing efficiency and end-use performance.

Application Method and Process Compatibility

The right adhesive must align with both your production capabilities and the skill level of your team. Application methods range from simple squeeze tubes and manual syringes to automated spray or robotic dispensing systems. Additionally, determine whether the adhesive cures at room temperature, with added heat, through moisture, or under UV light, and select a product that your factory setup can accommodate. Finally, consider viscosity and gap-filling ability—some adhesives are thin for close-fitting parts, while others easily fill gaps on rough or irregular surfaces.

- Application Technique: Manual, semi-automatic, or automated dispensing.

- Cure Type: Room temperature, heat-activated, UV-activated, or moisture-activated.

- Viscosity: Low for tight joints; high for gap filling.

Prioritizing application ease improves productivity and ensures process consistency for all levels of manufacturing.

Safety and Regulatory Considerations

Many industrial adhesives contain volatile organic compounds (VOCs) and other hazardous substances that require strict safety protocols. Ensure your chosen adhesive complies with all relevant workplace safety and environmental regulations. If your application involves sensitive fields such as food packaging or healthcare devices, additional certification and safety documentation may be required. The U.S. Environmental Protection Agency provides guides on safer chemical selection for industrial use.

Test Before Full-Scale Implementation

Before deploying an adhesive across your entire production line, run thorough performance testing under real-world conditions. Standardized tests include peel, shear, and tensile strength measurements, as well as environmental aging and accelerated fatigue trials. Ideally, collaborate with adhesive manufacturers or suppliers to obtain samples and technical support tailored to your actual substrates and process conditions.

- Peel and shear tests

- Environmental resistance and aging trials

- Realistic bonding trials on production substrates

Validating adhesive performance in your own facility ensures a reliable, scalable fit for your products.

Final Thoughts

Selecting the right industrial adhesive is a strategic decision that impacts every aspect of product quality, manufacturing efficiency, and customer satisfaction. By thoroughly understanding your materials, environmental demands, necessary mechanical properties, and regulatory needs, you’ll lay the foundation for consistent, durable bonds every time.