Introduction to Repmold

In the fast-paced world of technology and innovation, staying ahead means embracing new tools that can transform how we work. One such groundbreaking tool is Repmold. It has emerged as a game-changer for industries looking to enhance efficiency and productivity. But what exactly is Repmold? How does it function, and why should you care about it?

Whether you’re an industry professional or simply curious about modern tech solutions, understanding Repmold could open up exciting possibilities for your projects. This blog post will unravel the mystery behind this innovative tool, explore its key features, highlight real-world success stories, and offer tips on how to utilize it effectively. Let’s dive into the fascinating world of Repmold together!

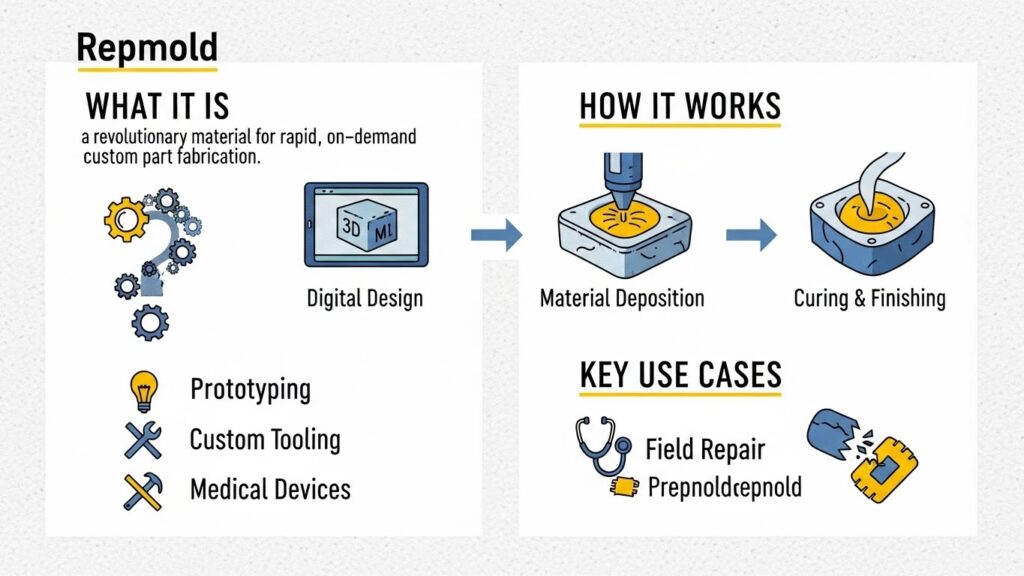

What is Repmold and how does it work?

Repmold is an innovative technology designed to streamline the mold-making process in various industries. It leverages advanced materials and techniques to create molds that can be easily replicated. This means manufacturers save time and resources while maintaining high standards of quality.

The core principle behind Repmold lies in its ability to produce durable, lightweight molds quickly. Using a combination of 3D printing and traditional molding methods, it allows for precise design customization. The result is a product tailored to specific needs without extensive lead times.

Once created, these molds can be used multiple times, enhancing efficiency in production lines. This adaptability makes Repmold particularly appealing for companies looking to reduce waste and improve sustainability efforts.

By integrating digital technologies with physical manufacturing processes, Repmold represents a significant advancement in mold innovation. Its impact reaches across sectors from automotive to consumer goods.

Key features of Repmold

Repmold stands out with its intuitive user interface. This design makes it easy for both novices and experts to navigate through the platform effortlessly.

Another notable feature is its real-time data processing capability. Users can access insights instantly, allowing for quicker decision-making in dynamic environments.

Flexibility is also a significant advantage of Repmold. It supports various industries, from manufacturing to healthcare, adapting smoothly to different workflows without compromising functionality.

Collaboration tools within Repmold enhance teamwork. Teams can share information seamlessly, fostering communication and boosting productivity across projects.

Robust security measures ensure that sensitive data remains protected at all times. This commitment to security builds trust among users who prioritize confidentiality in their operations.

Case studies of successful implementation of Repmold

One notable case study involves a leading automotive manufacturer that adopted Repmold to streamline its production process. By integrating this technology, the company reduced lead times by 30%. The flexibility of Repmold allowed them to quickly adapt designs for various vehicle models without extensive downtime.

Another example is in the aerospace sector, where a major firm implemented Repmold to enhance their prototyping efforts. This transition enabled rapid iterations and testing of components, ultimately accelerating their product development cycle significantly.

Moreover, a consumer electronics brand leveraged Repmold in its injection molding processes. They reported improved accuracy and consistency across numerous product lines. This not only enhanced product quality but also minimized material waste.

These examples highlight how diverse industries are harnessing Repmold’s capabilities to drive efficiency and innovation in their operations.

Tips for using Repmold effectively

To make the most of Repmold, start by familiarizing yourself with its interface. A hands-on approach can help you navigate features more intuitively.

Next, leverage the documentation and community resources available. They often provide insights that go beyond basic usage, enhancing your overall experience.

Experiment with customization options to tailor workflows that suit your specific needs. Personalization helps streamline processes for better efficiency.

Regularly update the software to benefit from new features and improvements. Staying current ensures you’re using Repmold at its full potential.

Consider collaborating with colleagues who are also using Repmold. Sharing tips and tricks can lead to discovering innovative approaches together. Engaging in this way can enhance productivity while building a supportive network around the tool.

Potential drawbacks and limitations of Repmold

While Repmold offers numerous benefits, it’s essential to consider its drawbacks. One significant limitation is the learning curve associated with its implementation. Users may require training or extensive documentation to harness its full potential effectively.

Another concern lies in compatibility issues. Depending on existing systems and software, integrating Repmold can sometimes be challenging. This could lead to delays in deployment and potentially impact project timelines.

Moreover, performance can vary based on the scale of operations. Smaller businesses might find that certain features are underutilized due to a lack of resources or specific needs.

Reliance on any tool brings risks regarding data security and privacy. Organizations must ensure robust protocols are in place when using Repmold, as sensitive information could be at stake if not managed properly.

The future of Repmold and its impact on industries

The future of Repmold looks promising, as industries increasingly embrace digital transformation. This innovative tool is set to revolutionize manufacturing processes across various sectors.

As automation becomes a priority, Repmold will play a crucial role in optimizing workflows. By enhancing efficiency and minimizing errors, companies can streamline production like never before.

Moreover, the adaptability of Repmold means it can cater to diverse needs. From automotive to electronics, its versatility could reshape supply chains globally.

Sustainability is another critical aspect—Repmold encourages eco-friendly practices by reducing waste in production cycles. As environmental concerns grow, this feature will become indispensable for businesses aiming for greener solutions.

In essence, the integration of Repmold into everyday operations signifies not just an evolution in technology but also a shift towards smarter and more responsible industrial practices.

Conclusion

Repmold presents a transformative approach to manufacturing and production processes. Its ability to streamline operations while enhancing creativity makes it a game-changer in various industries. As organizations increasingly seek innovative solutions, Repmold stands out for its capacity to adapt and scale.

With the right strategies in place, users can maximize the benefits of Repmold. A thorough understanding of its features and capabilities is essential for successful implementation. Additionally, awareness of potential drawbacks ensures informed decision-making.

As technology evolves, so too will the applications of Repmold. The future looks promising as industries explore new ways to integrate this tool into their workflows. Embracing such advancements could lead to significant efficiency gains and inspire groundbreaking ideas that reshape traditional frameworks.

The journey with Repmold has just begun, offering exciting possibilities ahead. Engaging with this revolutionary concept may unlock untapped potential across various sectors, driving innovation forward into uncharted territories.